The Process

We are much more than just a mat rolling company, we engineer solutions that enhances the companies entire mat division.

Our complete analysis:

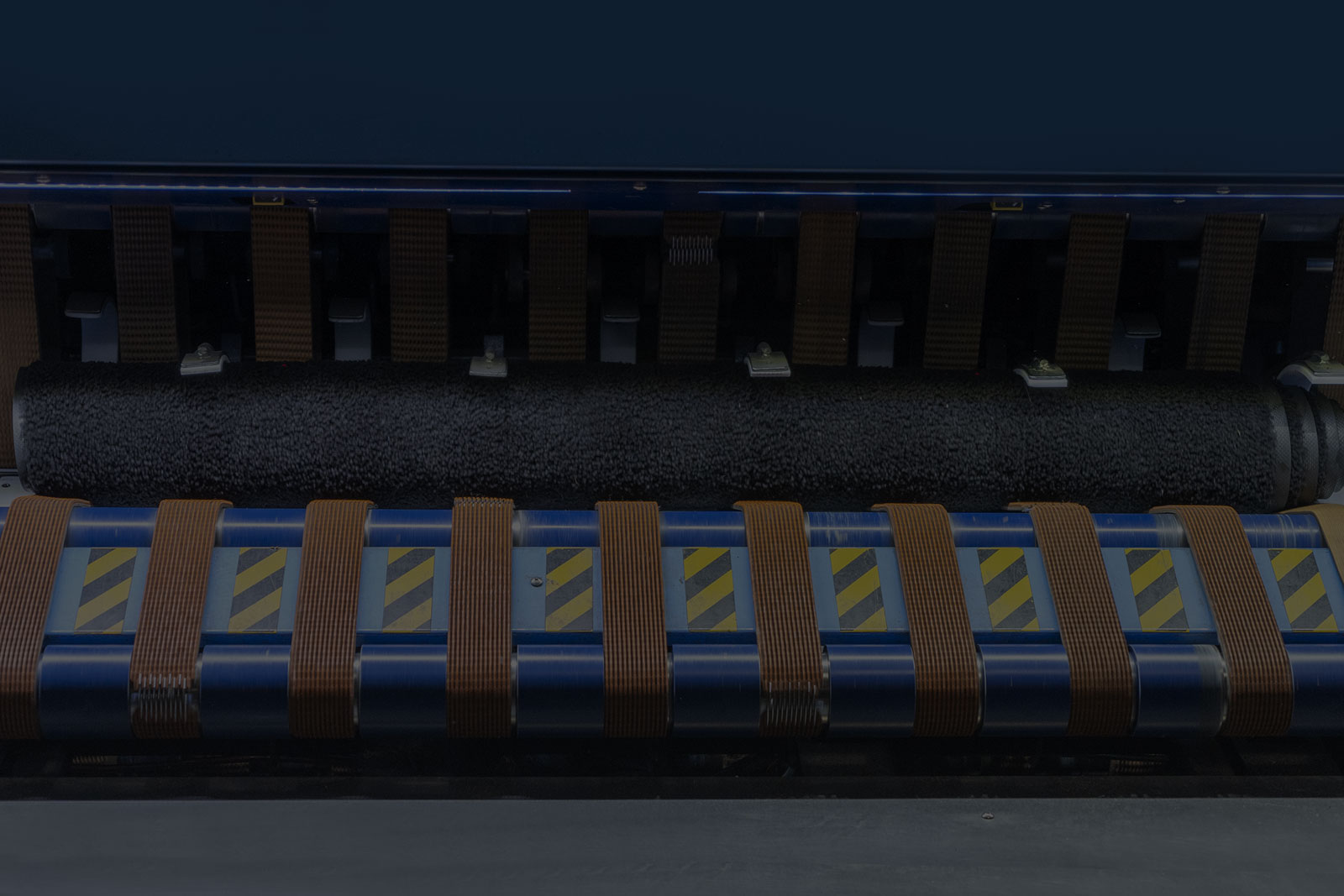

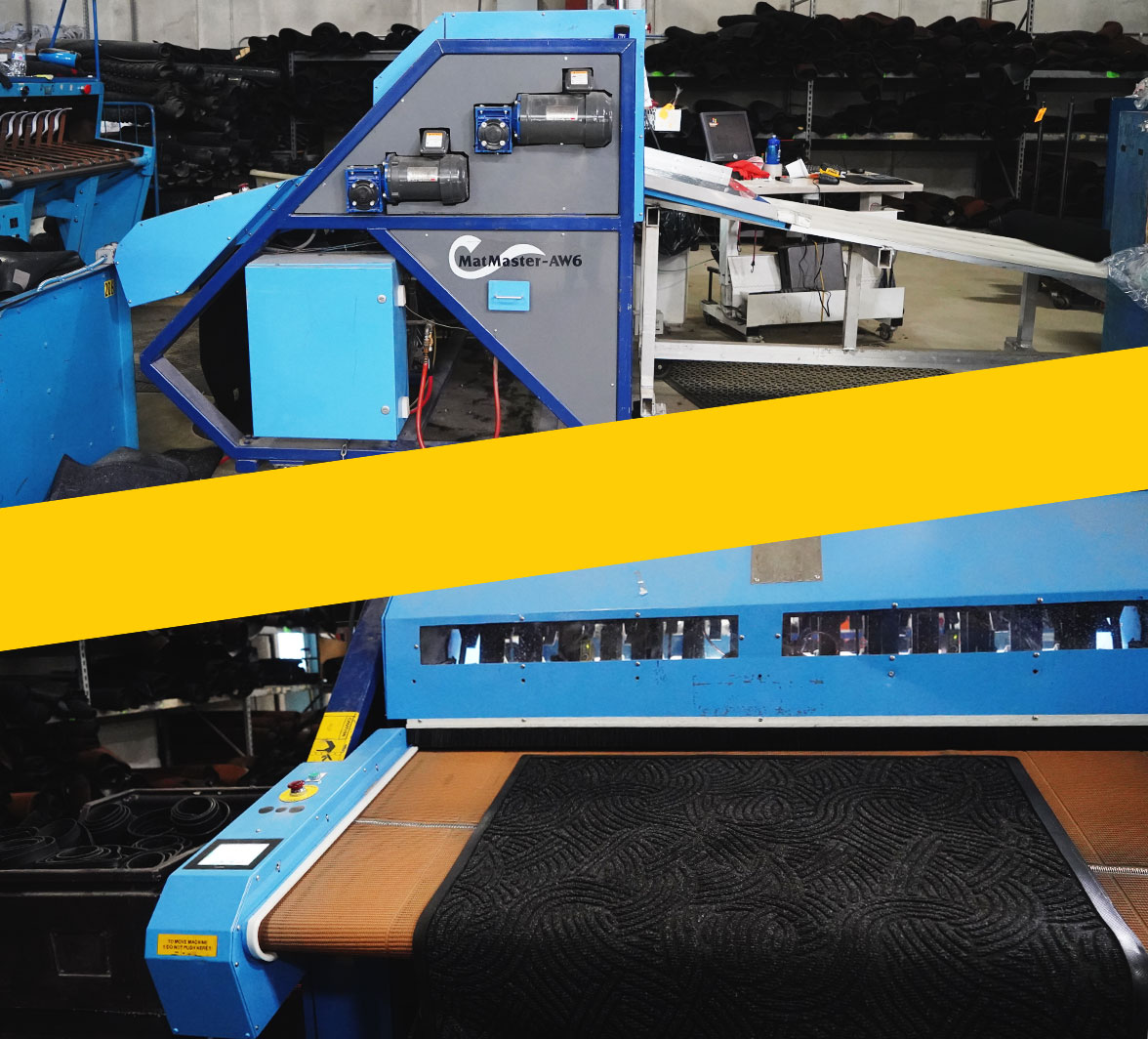

Mat Master AW6

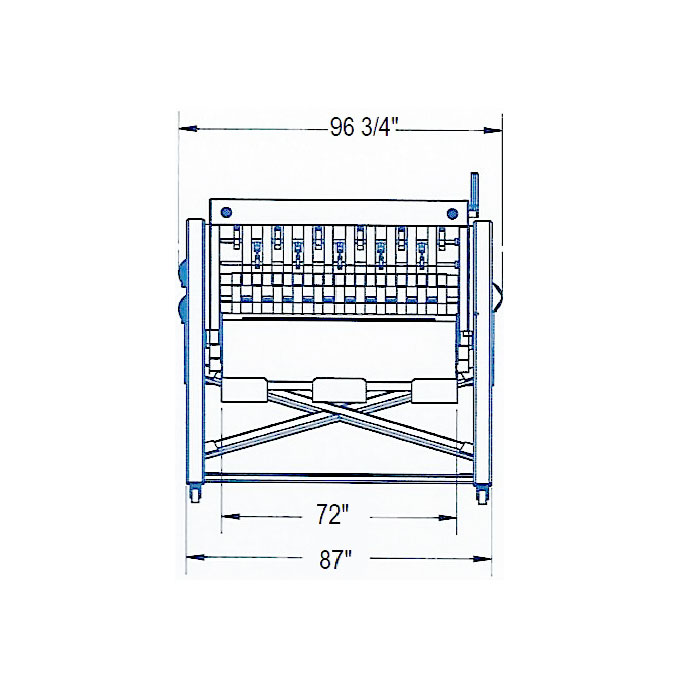

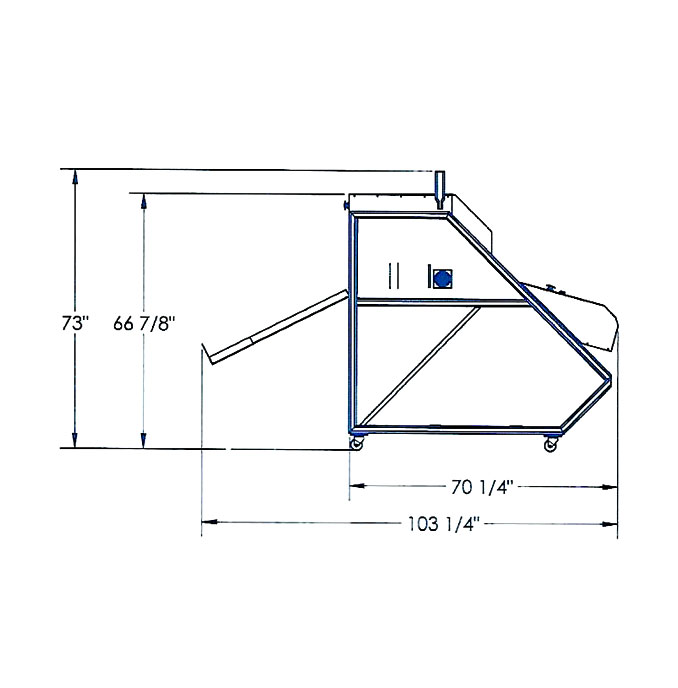

Specifications

* Air use based on unpressurized cylinder volume at 400 operations per hour